4.

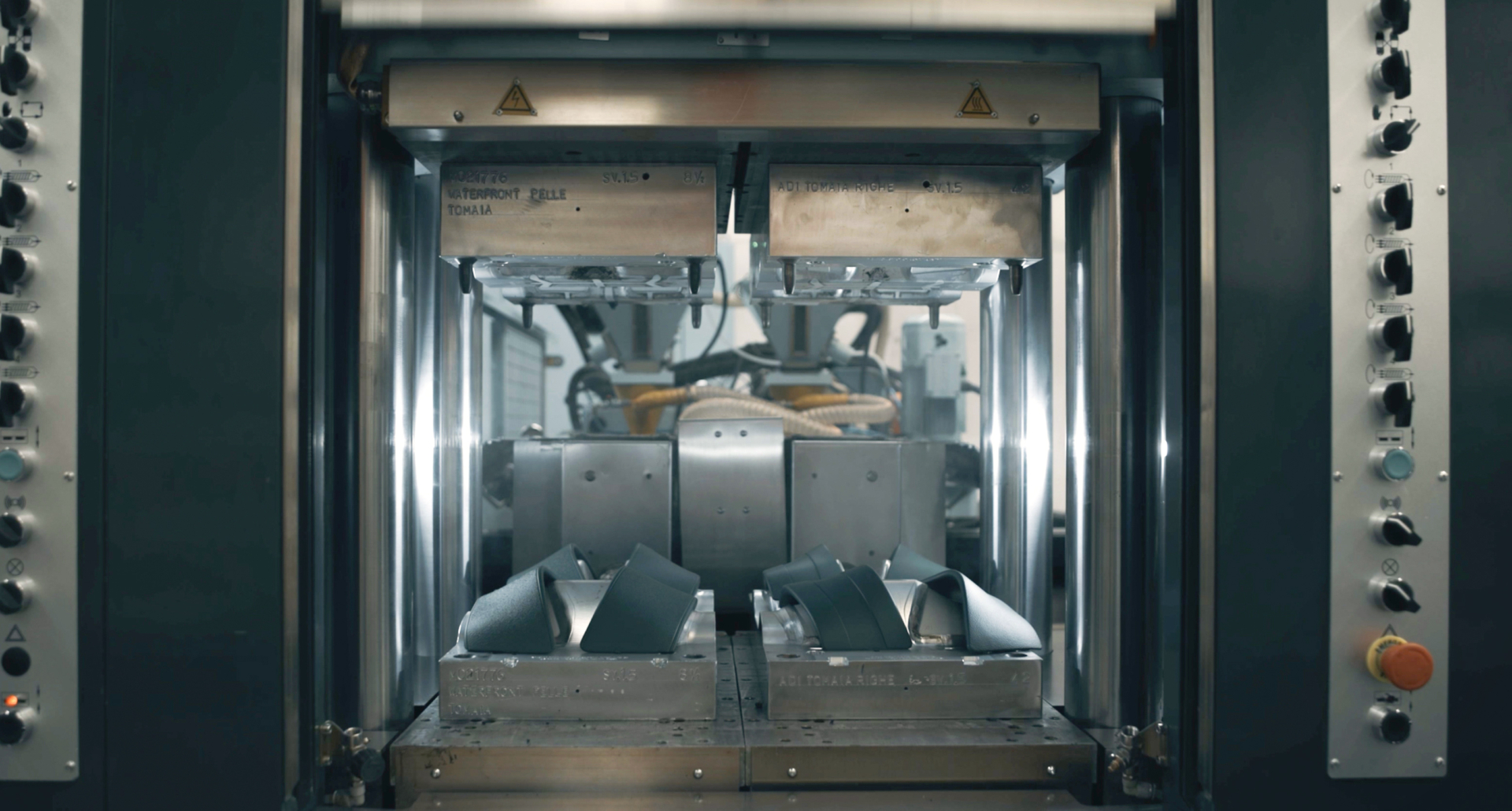

Moulding

Our company is equipped with the latest generation and most efficient moulding machines with a total of 154 in-line moulds and an annual production capacity of 3 million pairs of products.

Why we believe in EVA

EVA based materials are elastomeric rubbers that give products greater elasticity, softness and grip, similar to vulcanized rubber, while maintaining a low density and a specific weight up to four times lower than a rubber or a thermoplastic material.

EVA is an expanded crosslinked material, whose closed-cell molecular structure guarantees complete water impermeability and hydrolysis resistance.

Expanded EVA is resistant to fungi and bacteria, hypoallergenic and resistant to yellowing due to UV rays.

It is a non-toxic material and in case of disposal through traditional systems such as incinerators or waste-to-energy plants, it does not produce dioxin.

Thermoplastics

In thermoplastics division we have the latest generation of high tonnage machines, designed to ensure maximum quality and precision for a total of 25 moulds in line and an annual production capacity of 2 million pairs of products.

We are specialists in the use of all thermoplastic materials including:

- TPU (Thermoplastic Polyurethane)

- PVC (Polyvinyl Chloride)

- SBS (Styrene-Butadiene-Styrene)

- SEBS (Thermoplastic Elastomer)

- ABS

The wide range of thermoplastic materials, combined with varied densities and hardness, enables the development of products with different mechanical and aesthetic characteristics, including:

- perfectly transparent items, glass effect

- gel items

- glittered items

- metallized items