Technology and

know-how at the service

of brands

Our organizational model, state-of-the-art facilities and know-how built over 40 years of experience allow us to offer our clients the highest quality products, flexible production and a significant advantage in time to market.

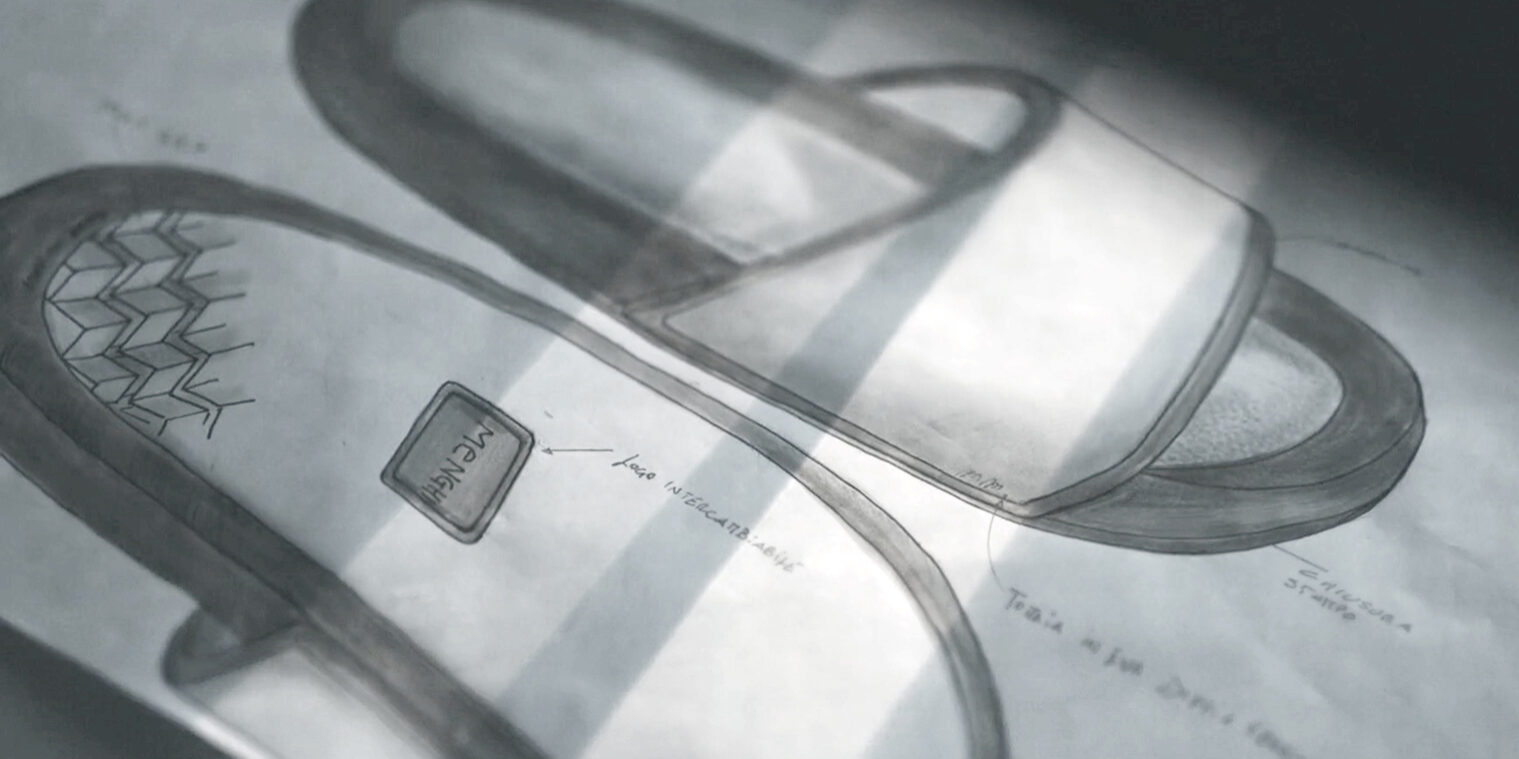

1. Design

We quickly model ideas, using different highly detailed 3D CAD software systems.

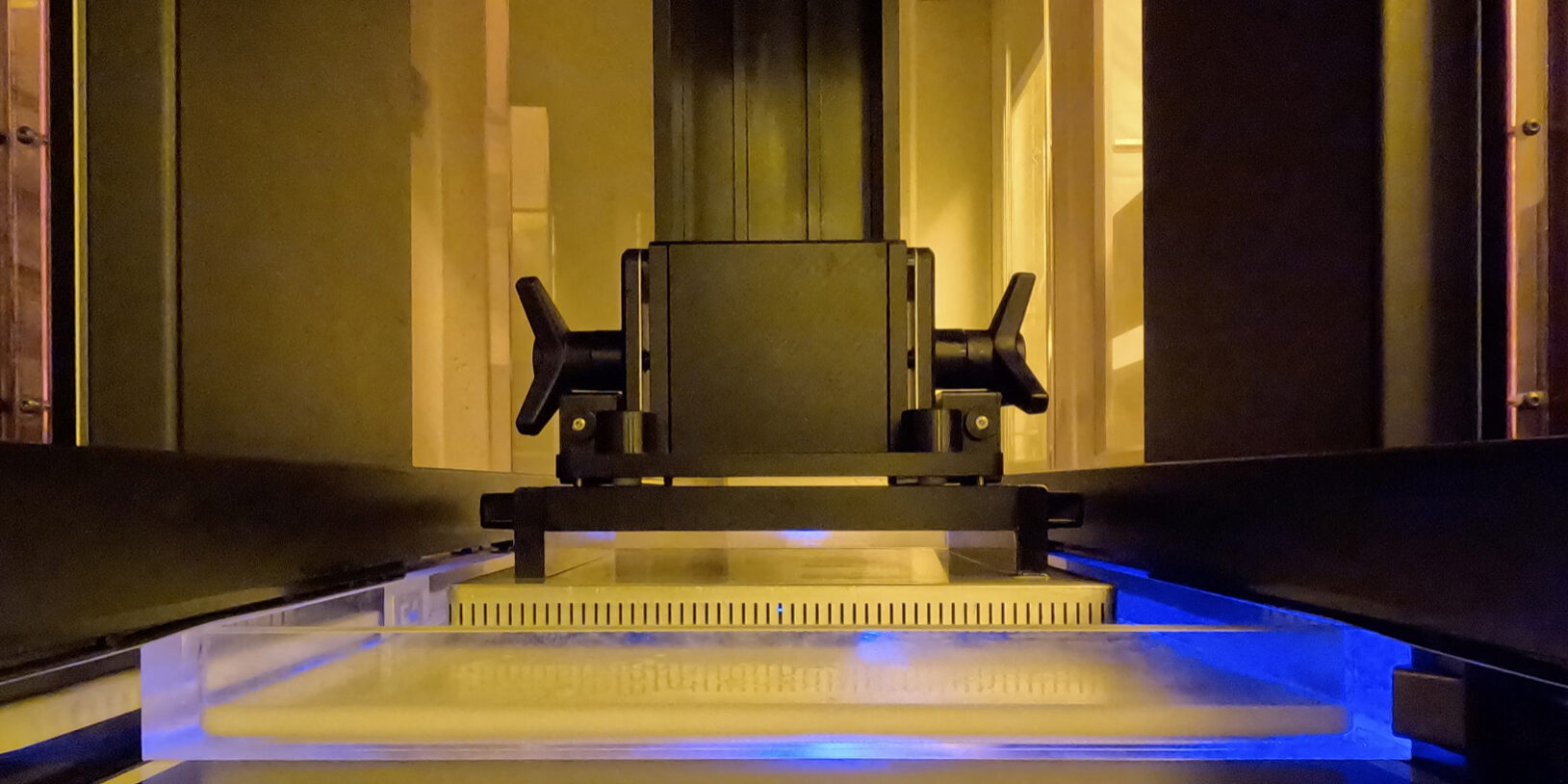

2. Prototyping

We develop high precision, high-quality prototypes with aesthetic and functional characteristics that strictly conform to the final product.

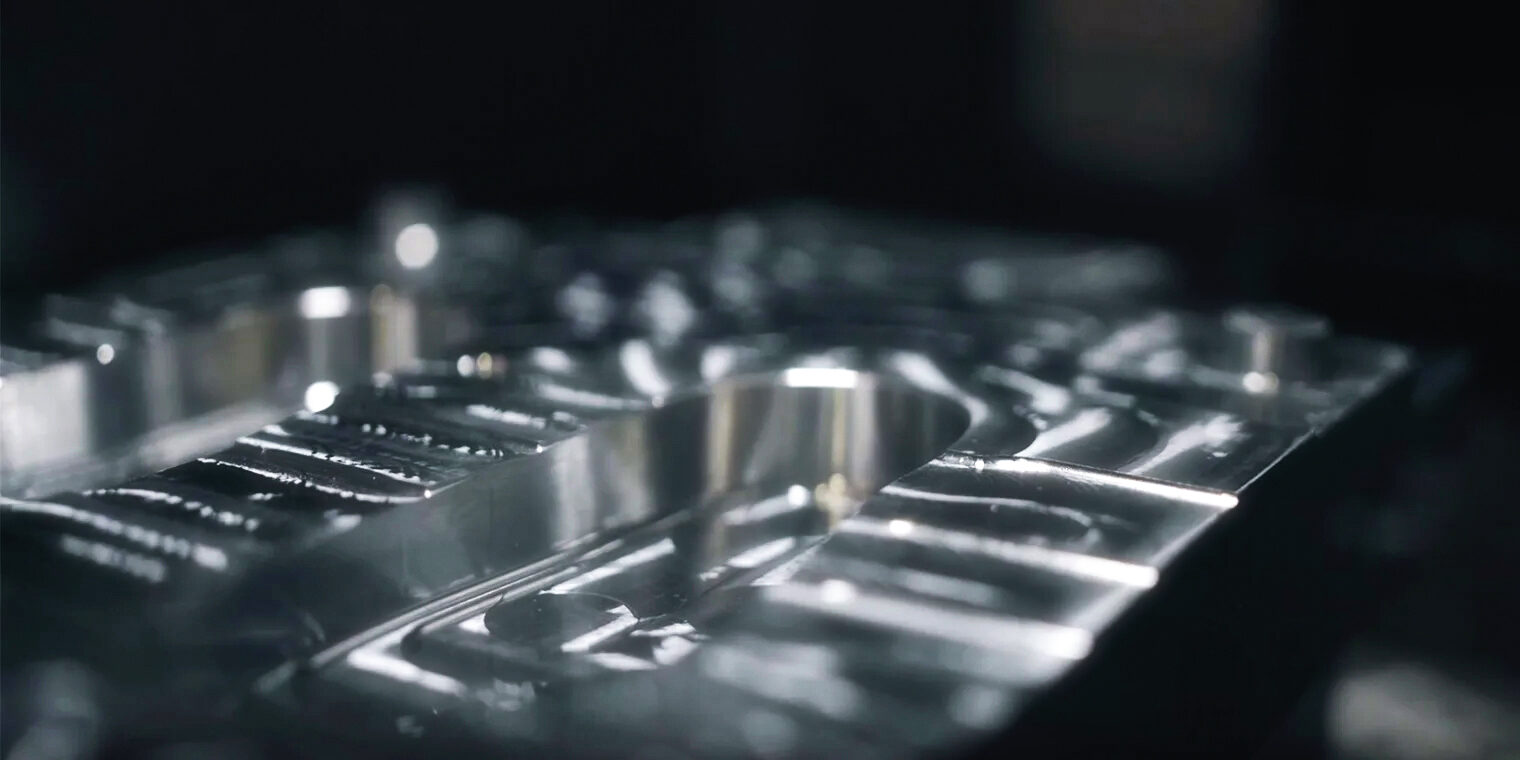

3. Moulds

Internal moulds workshop with, 5-axis fully automated machinery, and high production capacity up to 5,000 moulds per year.

4. Moulding

Our numbers: 3 million pairs of EVA Footwear per year and 2 million pairs of thermoplastics components.

5. Quality gate

We guarantee the highest quality standards for our products, thanks to highly specialized personnel dedicated to quality control, through all stages of the process.

6. Shoe factory and sole factory

We have 16 assembly lines with a production capacity of up to 16,000 pairs per day.