Grosso, the leading company in the mould making

The history of Grosso begins over 40 years ago, in the heart of the footwear district of the Marche region.

Acquired in 2020 by Menghi spa, today it is a leader in the design and manufacturing of moulds, mainly focused on the luxury footwear industry.

Through continuous investments in advanced machinery and the training of technicians and highly qualified labour, Grosso is committed to ensuring a rapid production process, optimized and aligned to the highest standards of the market.

The production plant is spread over a total area of 3,000 sqm of which:

- 800 sqm of office space

- 2,200 sqm for production

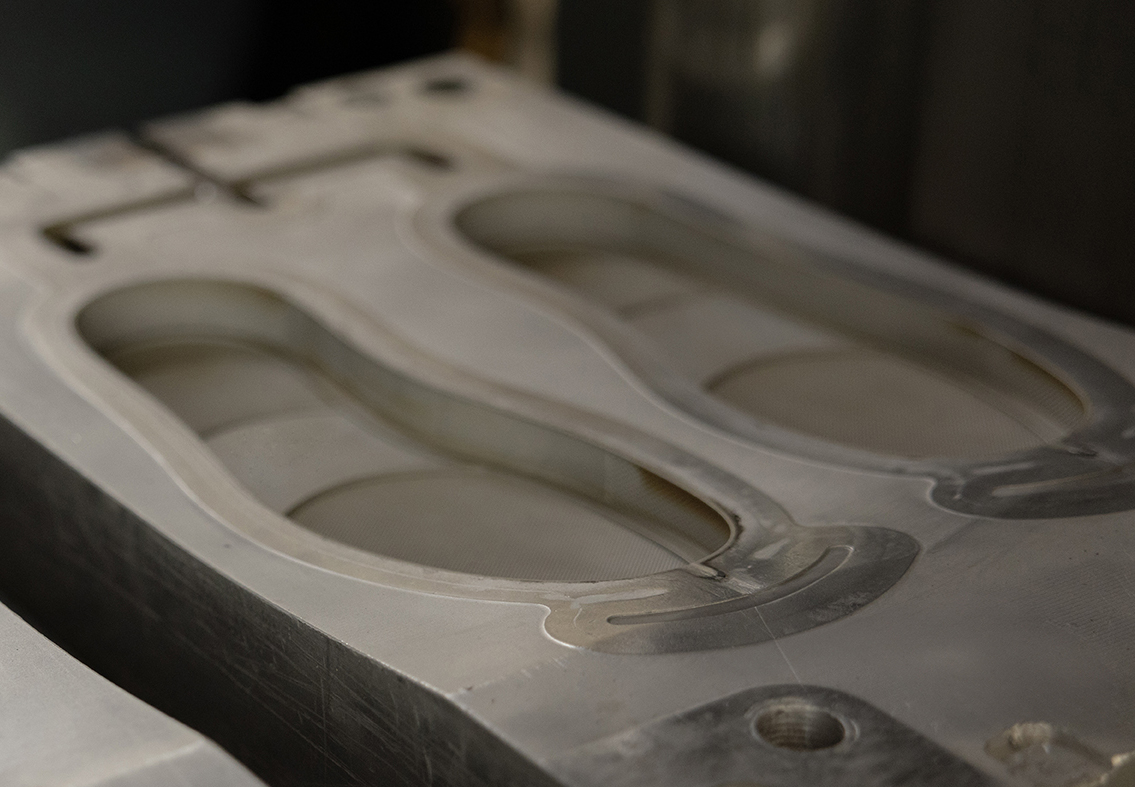

The process of designing and manufacturing of a mould follows several phases:

- design study, analysis of the idea proposed by the customer or three-dimensional optical scanning of the original shape provided by the customer

- 3D product design using CAD software systems

- construction of the physical prototype with Fast Cure machinery (SLA)

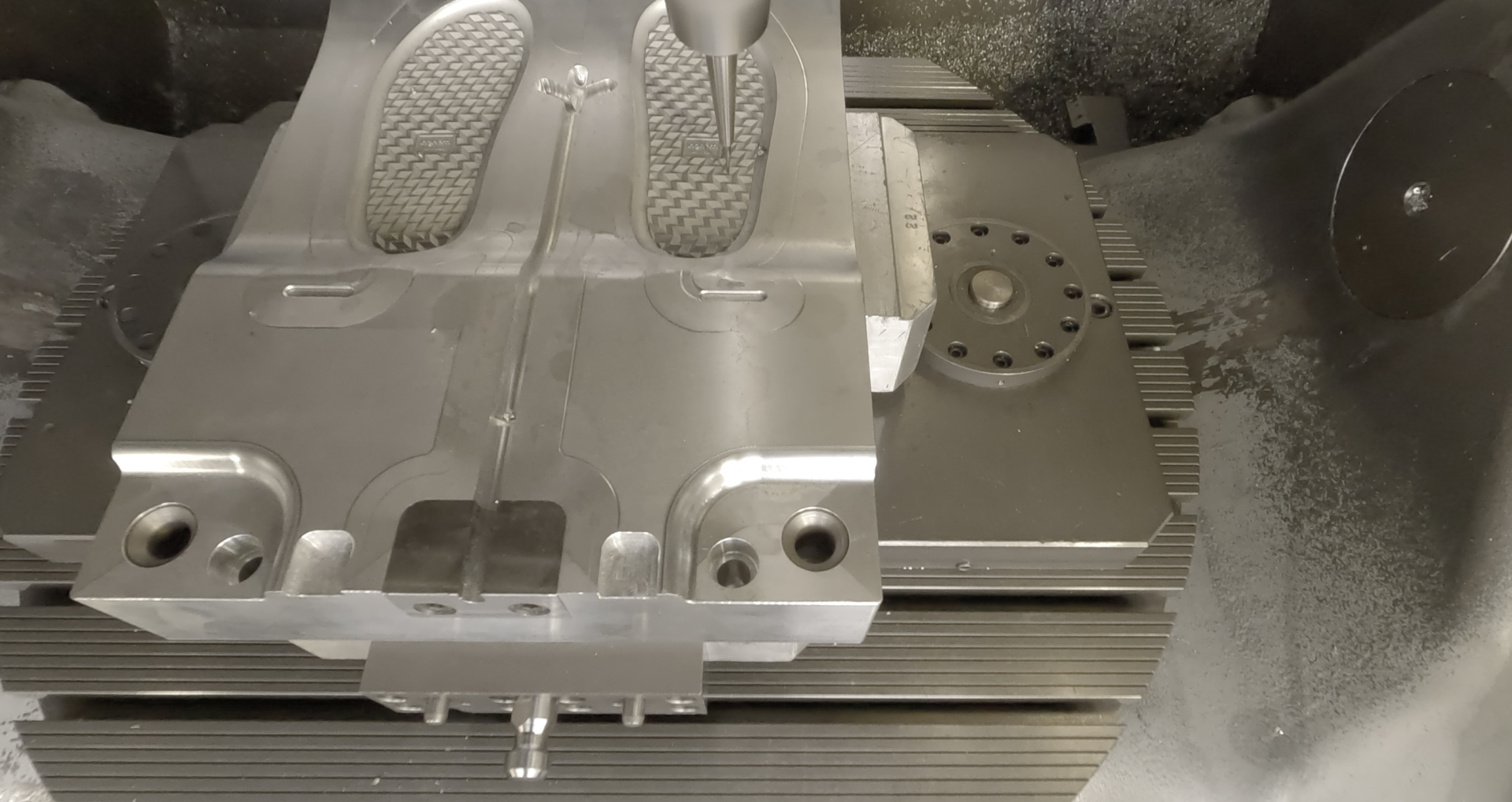

- mould manufacturing by using fully automated, high-speed precision machinery

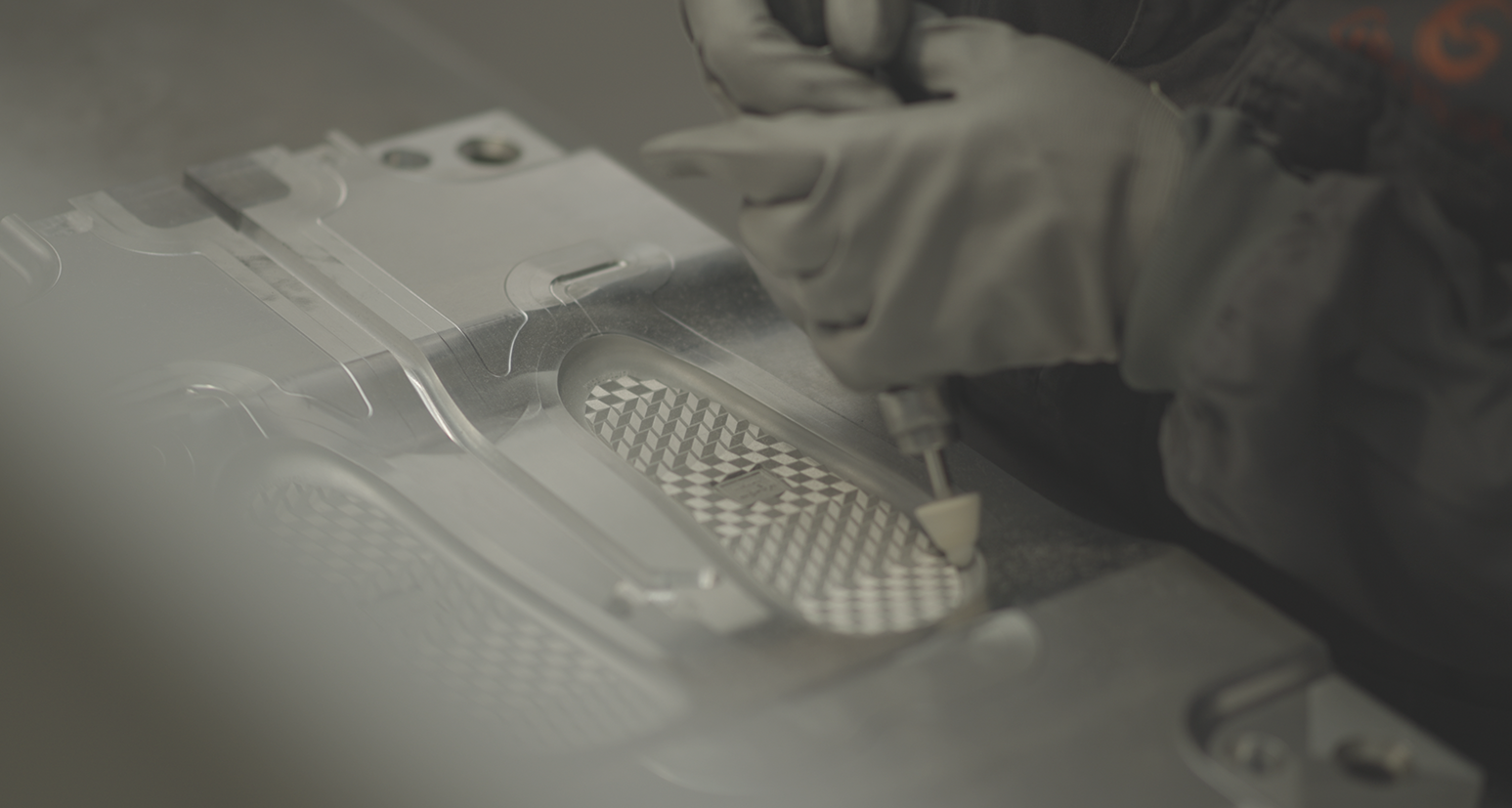

5-axis and 3-axis CNC machines shape the moulds to make products or components of any size, including the smallest details, finalizing the process with careful review and careful finishing.

The synergies between technology and craftsmanship are the secret to ensure high standards and rapidly deliver to the exacting specifications of the luxury sector.